Toner is something most of us use without giving it much thought. It sits inside the office printer, waiting to create crisp documents and colourful graphics. But what exactly is toner, and how is it made? Unlike ordinary ink, toner is a carefully engineered powder that plays a vital role in modern printing. In this article, we take you behind the scenes to explain how toner goes from tiny particles to perfect prints.

What toner is and why it matters

Before we look at how toner is produced, it helps to understand what it actually is.

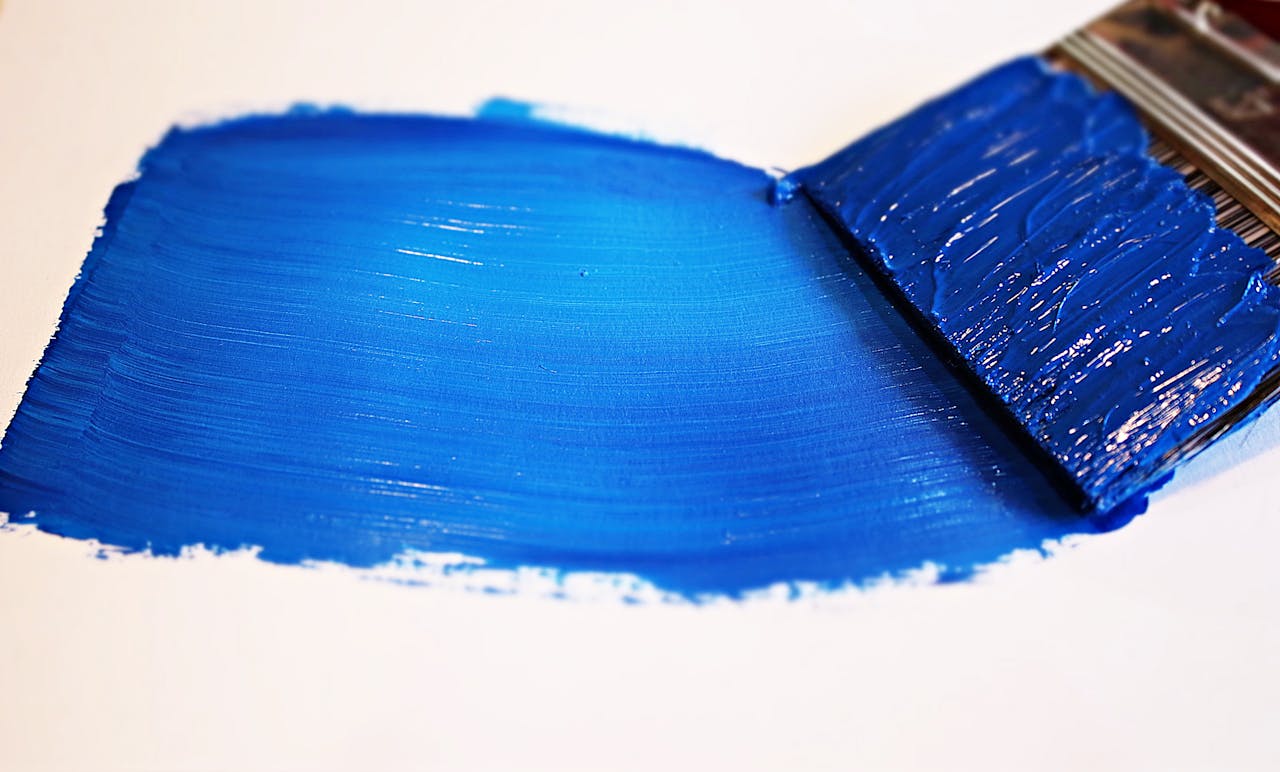

Toner versus ink

Toner is often confused with liquid printer ink, but the two are very different. Ink is liquid-based, while toner is a fine powder made from plastics and pigments. It is designed for use in laser printers and photocopiers, where heat and pressure fuse the powder onto paper.

The benefits of toner

Toner is popular because it produces sharp text, vivid colour and is capable of handling high-volume print runs. Unlike liquid ink, toner doesn’t smudge easily and can sit unused in a printer for long periods without drying out. This makes it ideal for busy workplaces and professional print environments.

How toner is made

Now let’s explore the step-by-step process of creating toner, from the raw materials to the finished cartridge.

Step 1: Mixing the ingredients

Toner starts with a blend of plastics, pigments and additives. The plastics (usually a type of polyester or styrene) act as a carrier, while pigments provide the colour – black, cyan, magenta or yellow. Additives are included to control the way the toner flows and melts.

Step 2: Melting and grinding

The ingredients are melted together into a resin-like material. Once cooled, this solid block is broken down and ground into fine particles. These particles are then carefully sifted to ensure they are consistent in size. The typical toner particle is only a few microns across – far smaller than a grain of sand.

Step 3: Microscopic shaping

Modern toner manufacturing often involves chemically grown particles. Instead of grinding down material, manufacturers can “grow” toner particles in a controlled chemical process. This makes the powder even more uniform, improving print quality and efficiency.

Step 4: Filling the cartridges

Once the toner powder is ready, it is loaded into cartridges designed for specific printer models. Each cartridge has built-in components that help distribute the toner evenly, ensuring the right amount reaches the paper during printing.

Step 5: From cartridge to paper

When you hit print, the laser printer uses an electrostatic charge to attract the toner particles onto the page. Heat and pressure then fuse the plastic powder permanently to the paper, creating the crisp text and images we all recognise.

Final thoughts

Toner may look like nothing more than coloured powder, but it is the result of a complex and highly precise manufacturing process. From carefully engineered plastic particles to advanced chemical methods, toner is designed to deliver consistent results with every print.

At SwiftPrint in Huddersfield, we rely on this technology every day to produce high-quality prints for our customers. Whether it’s business stationery, marketing materials or large-format banners, the journey from powder to perfect print is what keeps your designs looking sharp and professional.